Drying & Dehumidifying

WSDA Cabinet Dryer For Injection Molding Machine

Widely suitable for drying any plastic r...

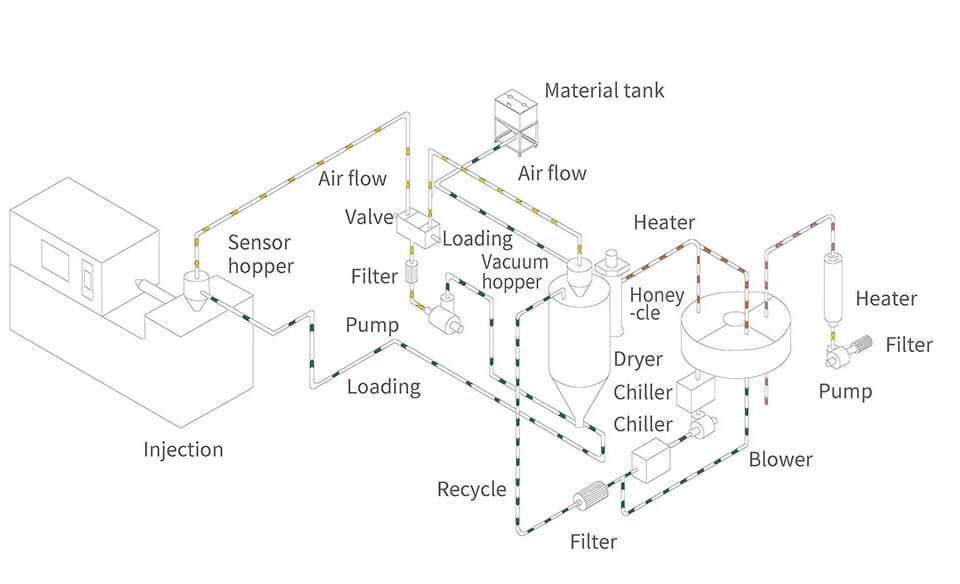

1:Integrated dehumidifying, drying and feeding into one unit.

2:Controlled by microprocessor with P.I.D. temperature control.

3:Double-condenser provides lower return air temperature and dew point below -40°C (-50°C is realizable with chilling water).

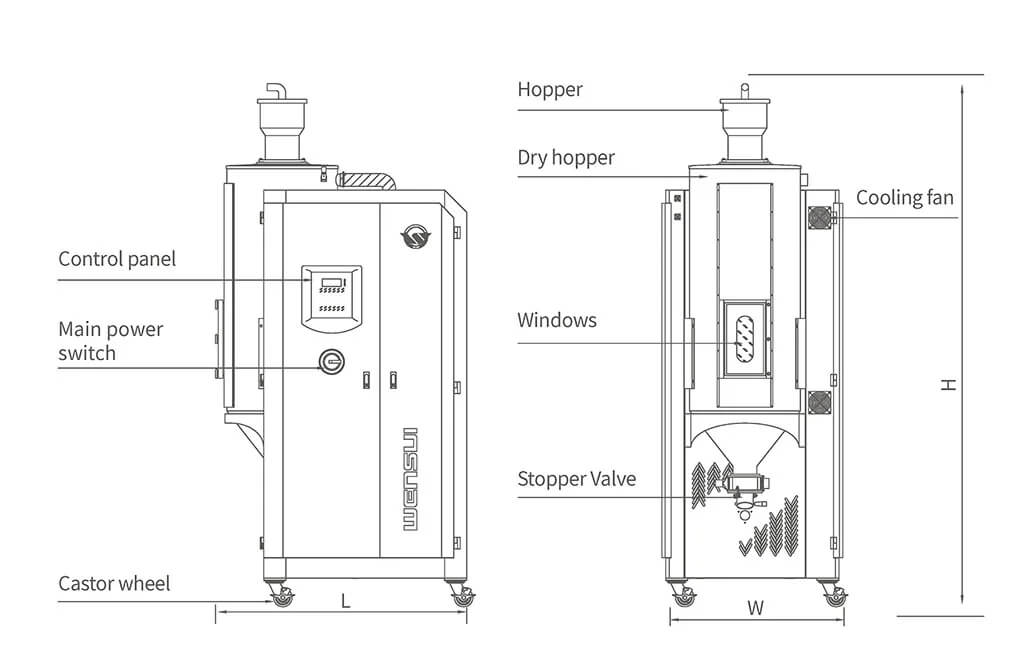

4:Insulating drying hopper with European standard

5:Fully sealed feeding system

6:Small footprint and high movability.

Performance characteristics

This machine integrates three functions: dehumidification, drying, and feeding.

The standard configuration for feeding is one to two: one magnetic spring hopper and one electric eye hopper.

Optional configuration is one to three: one magnetic spring hopper and two electric eye hoppers.

At most, it can be equipped with one trailing four: one magnetic spring hopper and three electric eye hoppers.

The drying and dehumidification control adopts microcomputer control, and P.1. D. temperature control.

LCD display, button operation, simple and easy to understand operation interface.

Adopting a dual cooler structure to ensure a lower return air temperature, the honeycomb can reach a dew point below -40 ℃

Enhanced freezing water can reach a dew point of -50 ℃ or even lower.

The operation interface is simple and easy to understand, and the text display of fault problems is clear at a glance.

The European style drying barrel design has strong insulation performance, effectively preventing heat dissipation and improving drying efficiency.

The closed loop feeding system can prevent the dried raw materials from getting damp again due to contact with external air

The feeding system is equipped with a cut-off valve device as standard, ensuring that there are no residual raw materials in the material pipe after each feeding is completed.

The integrated design has a small footprint and is easy to move, allowing for easy replacement of machines.

PLC human-machine interface control is optional (up to one dragging five can be selected for feeding).

Optional installation of dew point detector.

Note: The compressed air pressure should be greater than 0.4MPa and the flow rate should be greater than 15L/hr; Power supply: 3 Φ 380VAC 50Hz;

The product specifications are subject to change without prior notice.