Drying & Dehumidifying

WSDA Cabinet Dryer For Injection Molding Machine

Widely suitable for drying any plastic r...

Performance characteristics

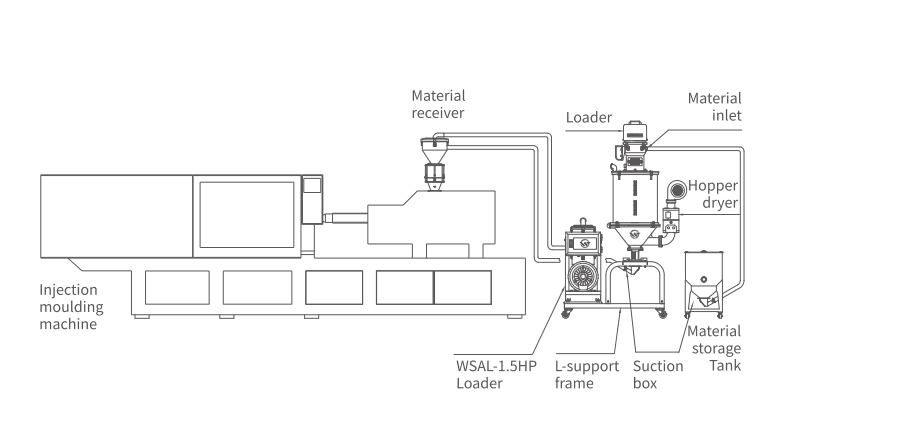

The automatic filling system consists of a dryer, suction machine, storage box, suction box, frame, etc. Its function is to automatically suck the raw materials in the storage box into the dryer through the WSAL-300G suction machine. The dryer heats and dries the raw materials, and then the suction box and WSAL-1.5HP suction machine work together to fill the raw materials into the injection molding machine. This automatically completes the entire process of heating, transportation, and control of raw materials from the storage box to the injection molding machine. This system has a high degree of automation, greatly saving manpower and power energy, improving work efficiency, and is an essential material supply system for injection molding processing.

The perfect combination of dryer and suction machine.

Save space and overcome height limitations in the factory building.

Convenient material replacement and cleaning, without the need for high-altitude operations.

The machine is easy to move and is very convenient for layout, operation, and maintenance.