Mixing & Dosing

WSVL Linear Vibrating Screen

Easy and fast screen replacement and cle...

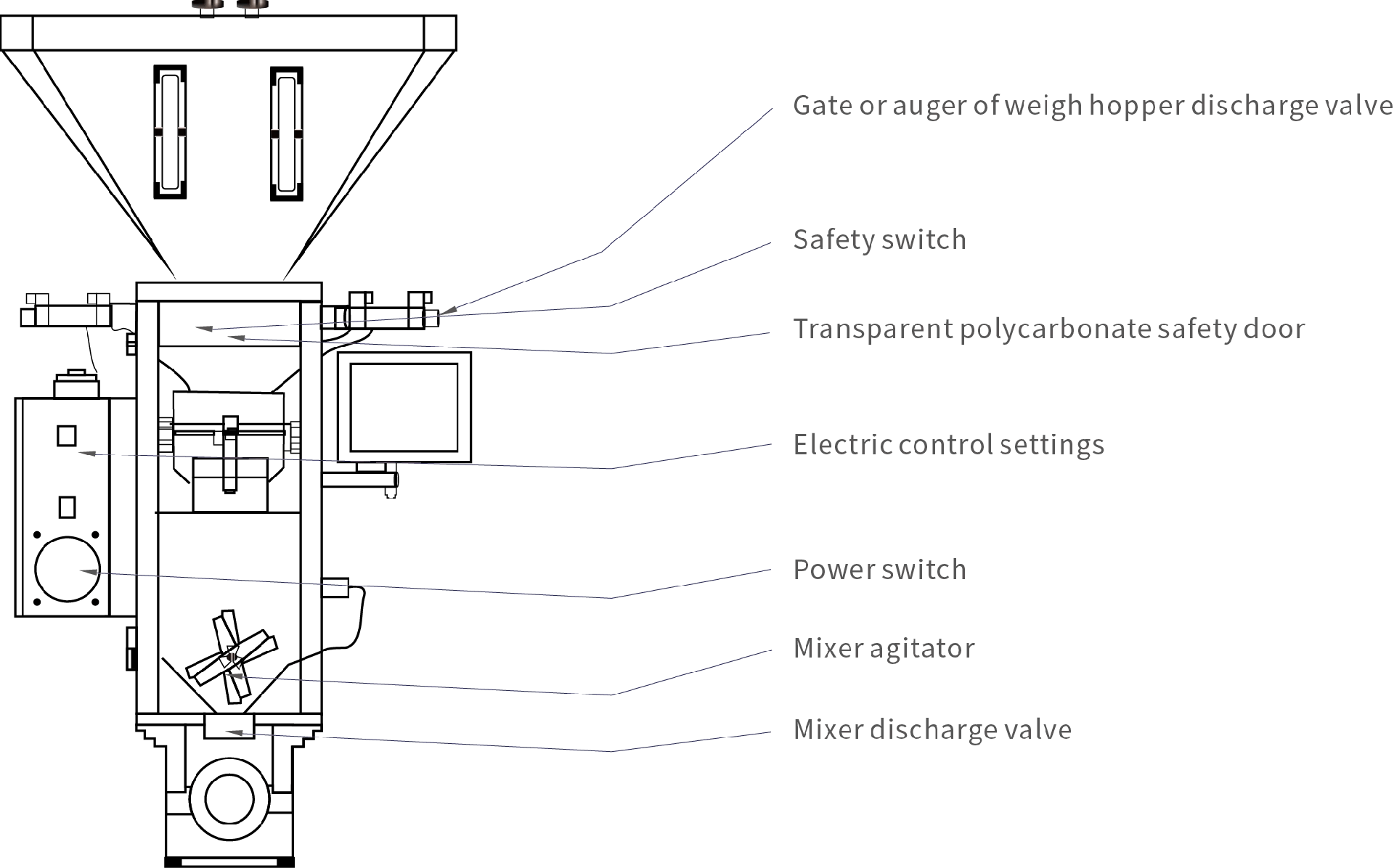

1:low-maintenance brushless gear motor.

2:The controller can save up to 50 sets of data.

3:Material changing is quick and safe with an easy access.

4:The speed of the screw can be controlled.

5:The controller is programmed with advanced calculation method for precise measurements.

Performance characteristics

All materials are evenly mixed after gravity measurement, and precision can be strictly controlled;

Advanced ingredient algorithm, which can accurately control and measure the proportion of each processing raw material;

Automatic repeated calibration function, which will automatically correct and adjust after each weighing to ensure the best ingredient accuracy;

Up to 6 types of raw materials can be processed simultaneously;

Modular and detachable structural design, easy to clean;

With formula storage function, it can store up to 20 sets of formulas;

The standard equipment is machine mounted (equipped with a standard base and manual closing plate), and an air operated discharge valve and ground mounted foot stand are also available as options;

When this machine is used for ground installation, it needs to be equipped with a tripod, pneumatic discharge valve, storage bucket, and suction box;

Equipped with alarm history recording function;

Standard USB data export function is equipped to save and record the ratio data for easy production quality management;

When changing to the European safety circuit type, add "CE" after the model.

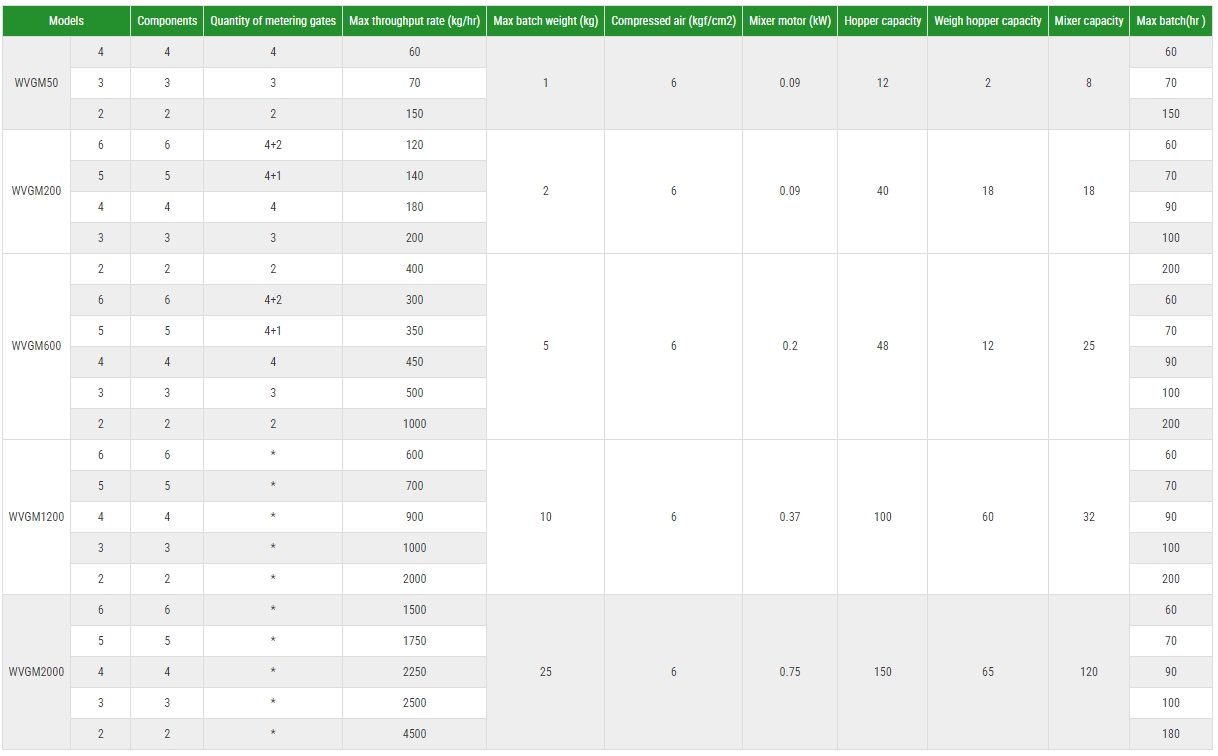

Note: 1) Mixing ratio error refers to the difference between the set percentage of each component and the actual percentage;

2) The knife metering valve is suitable for a ratio of 5% or more, and the mixing ratio error can be controlled within ± 0.3-0.5%;

3) The screw or micro meter is suitable for a ratio of 5% (excluding) to 0.5%, and the mixing ratio error can be controlled within ± 0.2%;

4) The above maximum processing capacity and mixing ratio error data are measured using uniform raw materials with a stacking density of 0.7kg/L and a diameter of 3-4mm through continuous operation. The maximum output will vary depending on the amount and proportion of the measured components;

5) The machine voltage specification is: WVGM200 and below models: 1 Φ 230VAC, 50Hz; WVGM600 and above models: 3 medium 380VAC, 50Hz;

The product specifications are subject to change without prior notice.