Temperature Control

WSIW Plastic Screw Chiller for Injection Molding

Adopting high-speed embedded microproces...

1:Equipped with a microprocessor, liquid-crystal display (LCD), and controlled buttons.

2:The control panel is user-friendly.

3:Easy to operate.

4:Adopted the PID control to ensure the mold temperature remains lower than ±5°C.

5:The electronics and heating system are separated to protect the machine from overheating.

6:High-quality and efficient pumps to comply with different molding temperatures.

7:The interior is made of stainless-steel to prevent corrosion and explosion while maintaining a constant temperature with high thermal efficiency.

8:The machine is protected from overloading, phase losing, overheating, and water shortage with a thermocouple alarm system

Performance characteristics

Adopting microcomputer control, LCD display, and button operation.

Adopting P.I.D. parameter self-tuning bi-directional (heating/cooling) control and segmented temperature control system, stable mold temperature can be maintained in any state, with a temperature control accuracy of up to ± 0.5 ° C.

It can switch between Chinese and English, and the operation interface is simple and easy to understand. The text display of fault problems is clear at a glance.

The separated design of electrical appliances and heating devices effectively avoids damage to electrical appliances caused by high temperatures.

Adopting high-quality and efficient pumps, it can meet the temperature control requirements of various molds.

The interior is made of stainless steel, which is corrosion-resistant, high-pressure explosion-proof, with a long constant temperature time and high thermal efficiency.

Six major protection functions: thermocouple disconnection alarm, power phase loss protection, reverse phase protection, overload protection, overheating protection, and water shortage protection.

Technical Parameter

| Model | Heat transfer media | Maximum temperature | Pump Power(kW) | Pumping flow (L/min) | Pump lift(m) | Capacity(L) | thermal power(kW) | Heat medium inlet and outlet diameter(inch) | Overall dimensions (cm) | Net Weight(kg) |

| WSTW-06X | Clean water | 95°C | 0.37 | 48 | 30 | 6 | 12mm×3 | 88×31×74 | 60 | |

| WSTW-09X | 0.75 | 60 | 45 | 9 | 12mm×3 | 88×31×74 | 60 | |||

| WSTW-12X | 1.5 | 110 | 45 | 12 | 12mm×4 | 88×31×74 | 60 | |||

| WSTW-24X | 2.2 | 340 | 26 | 24 | 12mm×4 | 110×44×109 | 120 | |||

| WSTW-36X | 3.75 | 410 | 35 | 36 | 1.5" | 110×44×109 | 130 | |||

| WSTW-60X | 3.75 | 470 | 35 | 60 | 1.5" | 110×44×109 | 135 | |||

| WSTW-06X-D | 0.37×2 | 48×2 | 30 | 6×2 | 12mm×6 | 90×43×120 | 98 | |||

| WSTO-06X-D | Heat transfer oil | 160°C | 0.37×2 | 48×2 | 30 | 10×2 | 6×2 | 12mm×6 | 90×43×120 | 102 |

| WSTO-06X | 0.37 | 48 | 30 | 10 | 6 | 3/8"×3 | 88×31×74 | 62 | ||

| WSTO-09X | 0.75 | 60 | 45 | 10 | 9 | 3/8"×3 | 88×31×74 | 65 | ||

| WSTO-12X | 1.5 | 110 | 45 | 10 | 12 | 3/8"×3 | 88×31×74 | 75 | ||

| WSTO-24X | 2.2 | 340 | 30 | 10 | 24 | 3/8"×3 | 110×44×109 | 120 | ||

| WSTO-36X | 3.75 | 470 | 35 | 10 | 36 | 1.5" | 110×44×109 | 130 | ||

| WSTO-60X | 3.75 | 470 | 35 | 10 | 54 | 1.5" | 110×44×109 | 135 |

| Model | Maximum temperature.(℃) | Electrothermal(kW) | Pump Power(kW) | Pumping flow(L/min) | Pump lift(m) | Connecting pipe diameter(inch) | Overall dimensions(cm) |

| VTW-06X | 120°C | 6 | 0.37 | 48 | 30 | 3/8"×3 | 88×31×74 |

| VTW-09X | 9 | 0.75 | 60 | 45 | 3/8"×3 | 88×31×74 | |

| VTW-12X | 12 | 1.5 | 110 | 45 | 3/8"×4 | 88×31×74 | |

| VTW-24X | 24 | 2.2 | 240 | 30 | 3/8"×4 | 110×44×109 | |

| VTW-06X-H | 160°C | 6 | 0.55 | 30 | 45 | 3/8"×3 | 88×31×74 |

| VTW-09X-H | 9 | 0.75 | 45 | 60 | 3/8"×3 | 88×31×74 | |

| VTW-12W-H | 12 | 1.5 | 90 | 55 | 3/8"×4 | 99×31×74 |

| Model | Heat transfer media | Maximum temperature | Pump Power(kW) | Pumping flow(L/min) | Pump lift(m) | Capacity(L) | Thermal power(kW) | Heat medium inlet and outlet diameter(inch) | Overall dimensions(cm) | Net Weight(kg) |

| VTO-06X | Heat transfer oil | 250°C | 0.37 | 48 | 30 | 10 | 6 | 3/8"×3 | 88×31×74 | 62 |

| VTO-06X | 0.75 | 60 | 45 | 10 | 9 | 3/8"×3 | 88×31×74 | 65 | ||

| VTO-12X | 1.5 | 110 | 45 | 10 | 12 | 3/8"×4 | 88×31×74 | 75 | ||

| VTO-24X | 2.2 | 340 | 30 | 10 | 24 | 3/8"×4 | 110×44×109 | 120 | ||

| VTO-36X | 3.75 | 470 | 35 | 10 | 36 | 1.5" | 110×44×109 | 130 | ||

| VT0-60X | 3.75 | 470 | 35 | 10 | 54 | 1.5" | 110×44×109 | 135 |

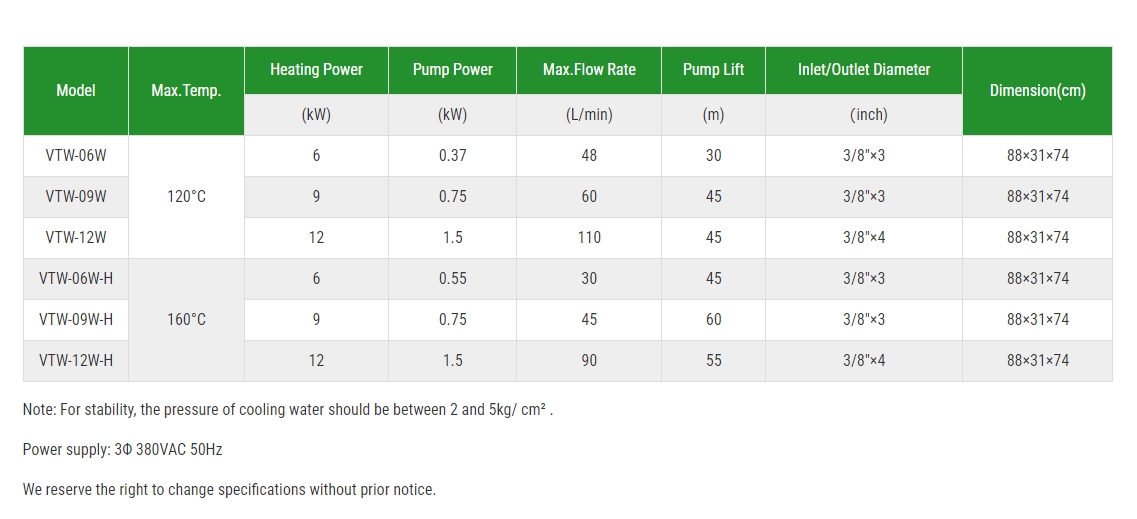

Note: To ensure the stability of heating temperature, the cooling water pressure should be between 2-5kg/cm2;

Power supply: 3 Φ 380VAC 50Hz.

The product specifications are subject to change without prior notice.

Temperature Control

Adopting high-speed embedded microproces...

Temperature Control

The application of a chiller in the cool...

Temperature Control

The application of a chiller in the cool...