Advantages and Disadvantages of Centralized Feeding Systems versus Standalone Conveyance

2023-12-28 Page view:

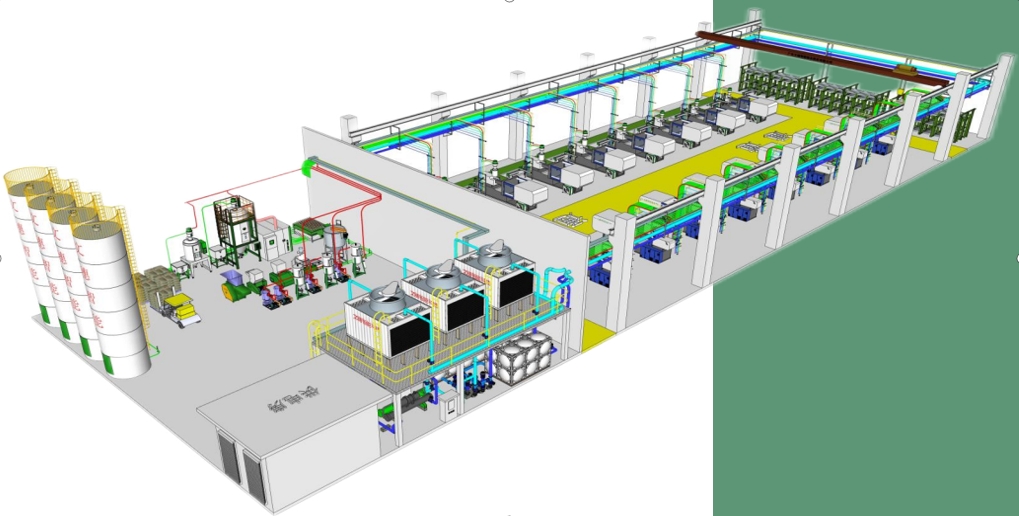

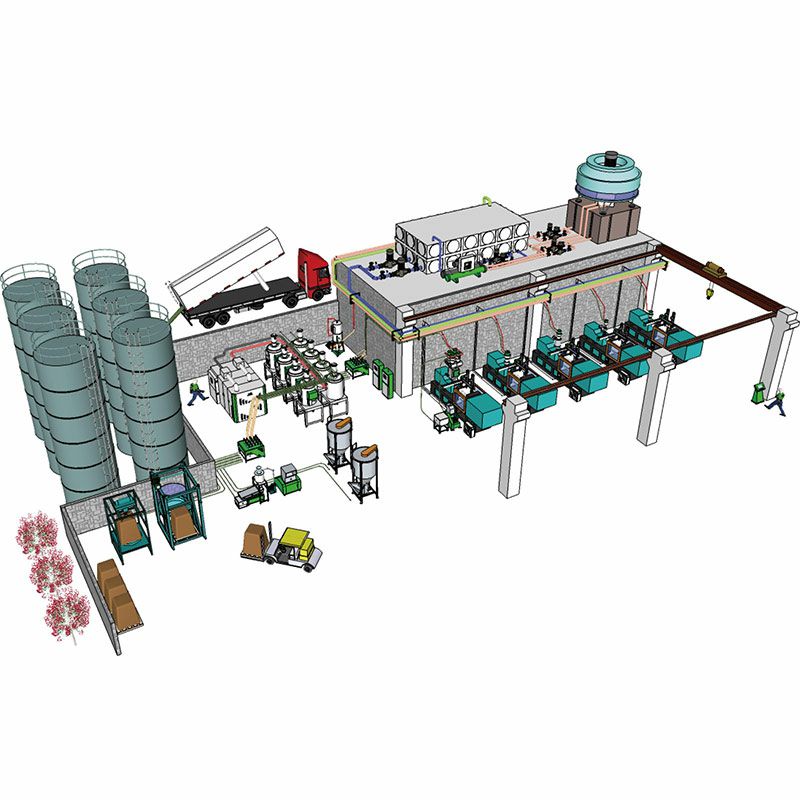

With the development of industrial technology and the demand for increased efficiency, the feeding of molding machines is moving towards automation, intelligent, and human-centric control. Feeding methods mainly consist of systems and standalone approaches. Selecting between the central feeding system or standalone conveyance in injection molding machines requires consideration of various factors and conditions to assess the most suitable equipment for production.

Firstly, consider production requirements, molding processes, product structures, and processing capabilities.

Secondly, factors such as upfront equipment costs, space occupancy, energy consumption, stability during usage, overall maintenance costs, and downtime due to faults need to be evaluated. In the entire plastic production process, numerous equipment components are necessary beyond common operations like dehumidification, drying, and feeding. Each manufacturing enterprise aims for cost-effective, high-efficiency, and stable equipment. How does one choose the optimal equipment? In plastic molding processes, how is the differencation and conserving energy. Centralized control can set different parameters and directly monitor them on the touch screen interface. In contrast, standalone control cannot centrally manage operations, resulting in prolonged operational times during startup, thus reducing efficiency.

Centralized control facilitates remote operations; one vacuum pump can supply multiple machines. For instance, if 10 injection molding machines require feeding, centralized control can be configured with just one vacuum pump, while standalone systems would need 10 material loaders, consuming more energy and lacking centralized operation capabilities.

1:Systems and standalone setups require different spaces. Centralized storage or stacking of raw materials, centralized dust collection, kept away from production areas, significantly improve working conditions near the main machines, thereby enhancing a clean and productive workshop environment, ensuring unpolluted raw materials. Standalone systems require more space for material placement, which might result in disorderly material storage, prone to errors during material addition, and lack centralized dust collection. A centralized feeding system reduces manual material handling, thus lowering labor intensity.

2:In centralized material feeding, if dehumidification and drying are necessary, they are also centrally managed, ensuring that materials remain moisture-free during transportation, with overall low electrical heating power. Material conveyance is enclosed, enabling control over the amount of material used in injection molding machines. If the workshop uses air conditioning, centralized heat management prevents heat from dispersing into the workspace, maintaining stable environmental temperatures. Standalone conveyance, however, concentrates all drying processes near the main machine, releasing heat directly into the workshop.

Centralized feeding systems enable various material conveyance options, allowing rational distribution based on preset material types, enabling quick material switches, unlike standalone systems, which cannot choose or switch materials for conveyance, operating only on a one-to-one supply basis.

1:Standalone conveyance offers greater flexibility in swapping; when a particular injection molding machine is idle, the supply can be stopped instantly. In contrast, if a system stops one vacuum pump, the corresponding injection molding machine (or other molding equipment) also ceases to receive supplies. Standalone machines can be shut down for maintenance without affecting other machines. However, a system can be equipped with standby pumps, ensuring uninterrupted operation during maintenance, resulting in higher workload for standalone machines than for systems. Standalone machines have more vulnerable components and higher operational costs.

Common Issues with Centralized Conveyance of Plastic Granules:

A plastic granule centralized conveyance system enables 24-hour continuous feeding, preventing blockages in material storage bins. However, system failures can reduce production efficiency and result in losses. Machine failures are inevitable, but identifying the root cause of the malfunction allows for its resolution and repair. Common faults in centralized feeding systems include:

Pump Overload:

1 Excessive dust in the dust collection bin clogs the filter, reducing airflow.

2 Issues with relays, thermal overload, or motor jams.

3 Pressure relief valves or mechanical valves on the dust collection bin malfunction, causing motor overheating.

Abnormal Conveyance:

1. Excessive dust accumulation in the dust collection bin clogs the filter, reducing pipeline airflow (insufficient suction), causing excessive pressure in the motor.

2. Problems with pneumatic valves failing to open or close properly.

3. When shared air tubes or material pipes leak, insufficient pressure at the starting point prevents material movement.

4. When connecting single material pipes for conveyance, ensure proper sealing.

5. Lack of material signals at multiple stations simultaneously.

6. Insufficient compressed gas affects pneumatic valve operations, leading to simultaneous operations at multiple locations, resulting in inadequate suction and incomplete material conveyance.

7. Failure to detect full material cups during material conveyance.

8. Errors in parameter settings.

9. Issues with photoelectric sensors indicating full material cups; the system continues to operate without receiving the signal to stop.